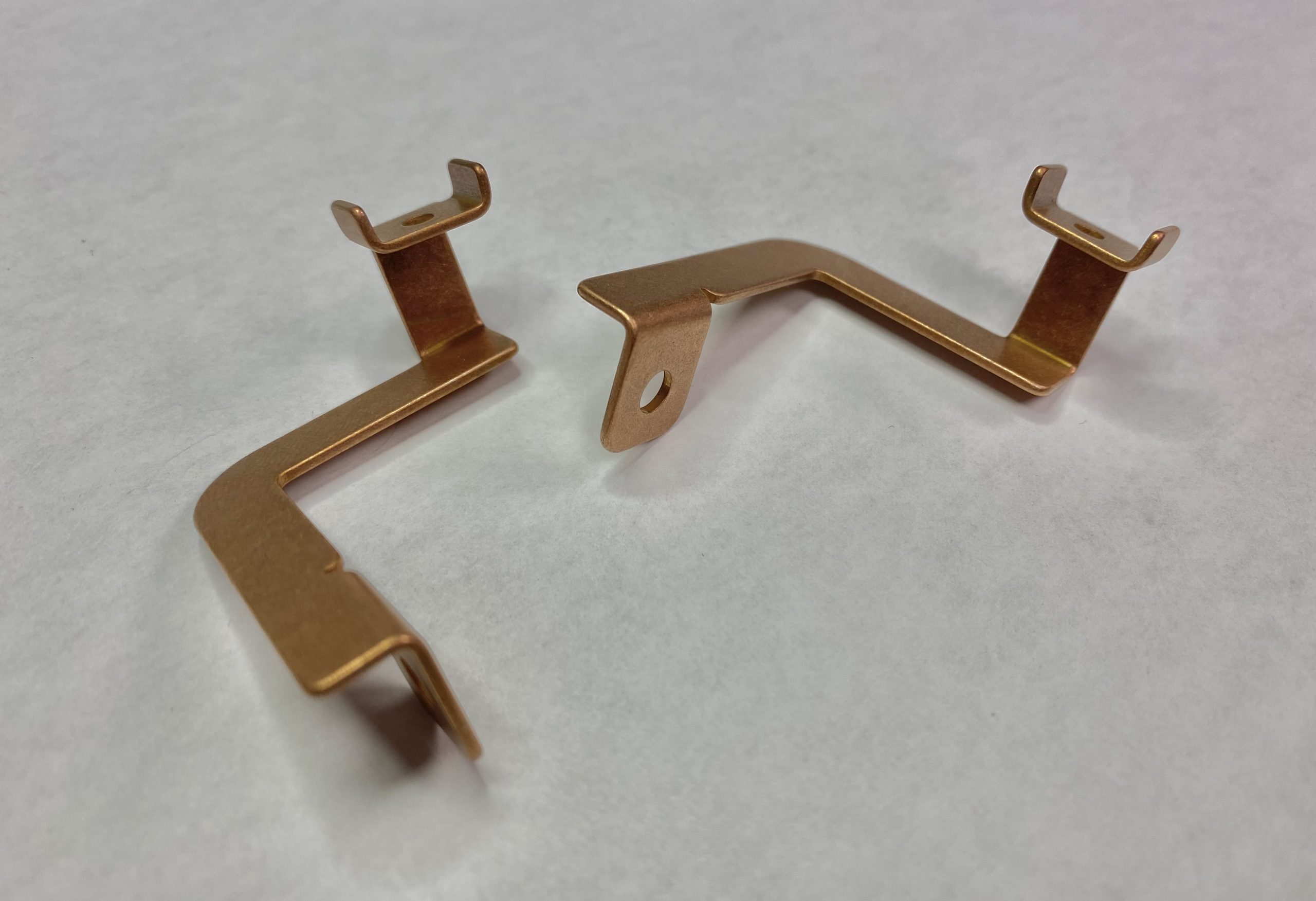

Welding and Fabrication

Since 1958 DI-EL Tool has specialized in Metal Stamping for the Aerospace and various other Commercial industries.

Our products include stand-alone parts, and component parts, engineered to meet customer specifications. DI-EL Tool’s ability to translate customer requirements into parts, holding extremely tight tolerances (both U.S. standard and metric) is unsurpassed in the industry. Our 7500 Sq. Ft, facility allows us to maintain redundant machines for repeat orders, and to assure uninterrupted product flow to meet stringent OTD requirements.

With 16 OBI presses ranging from 3 tons to 110 tons, we have the ability to produce parts from less than .005″ thick all the way up to .312″ thick.

We specialize in single station compound tooling, as well as progressive, and precision form tooling.